Rapid urbanization and industrialization are forcing organizations to increase their assets to meet market demand. RBI inspections can provide a more cost-effective approach over other traditional risk assessment procedures.

RBI Inspections now allow organizations and companies to categorize individual pieces of equipment or assets that they own by their risks. In this article, we explore applications of RBI analysis across different sectors.

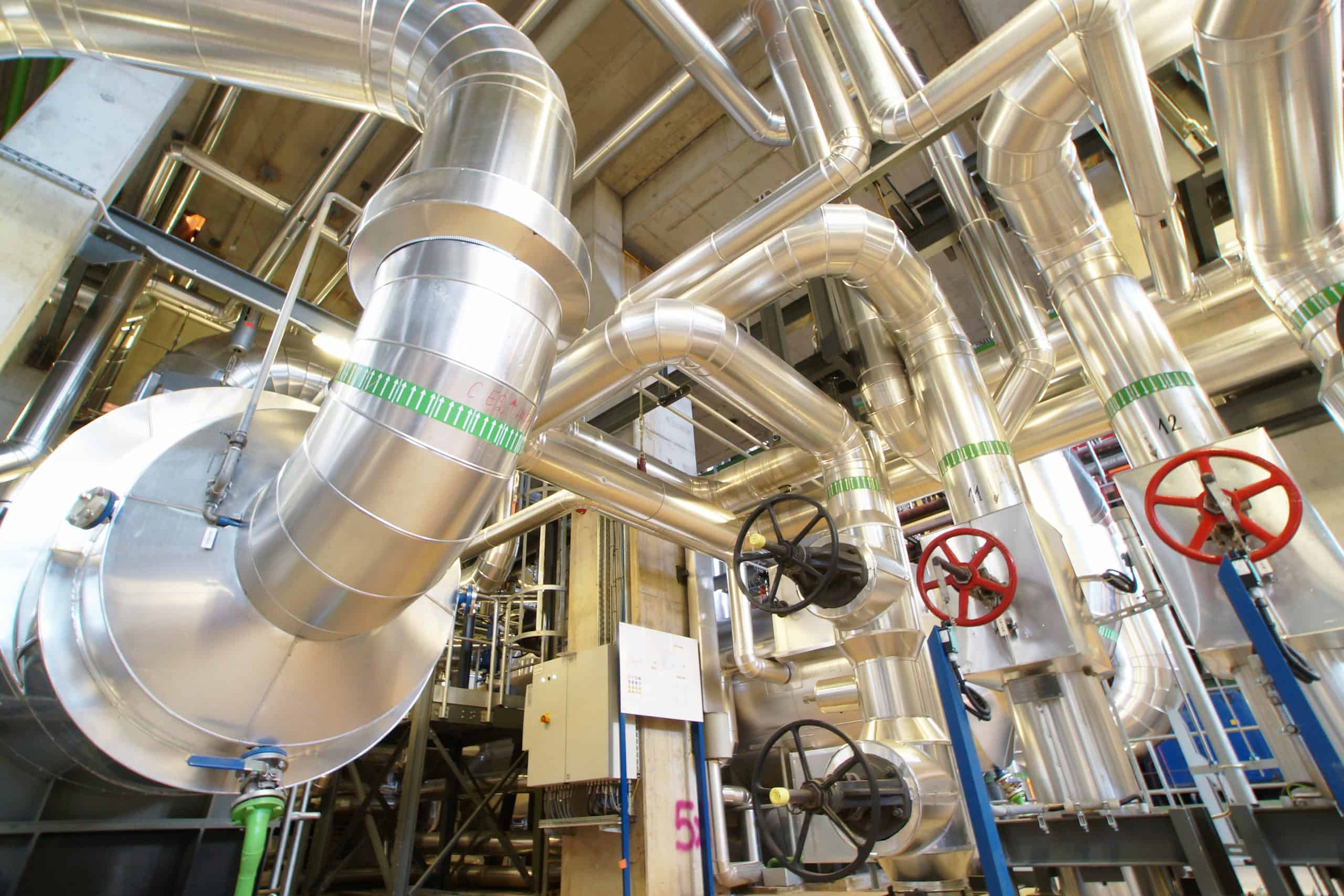

1. Power Generation and Utility Industry

Facilities in the utility and power generation industries have numerous safety and maintenance issues they have to address. They need to constantly assess the probability of failure, which is what risk-based inspections help them do. Personnel in the plant also need to apply safety protocols to avoid unnecessary faults and accidents. Maintenance is essential to ensure equipment in the plant does not degrade.

An organization may task an RBI inspection company with pinpointing asset management shortcomings for the plant. The company can customize Risk-Based Inspections to fit the dynamics of the energy industry.

2. Refineries and Processing Plants

Facilities in the petroleum sector were among the first to use RBI for industrial tank inspections. Oil plants have to consider the risk of fires from flammable materials. It may also include the impact of the industrial process on nearby ecosystems.

Above-ground oil tanks have many applications, but the primary goal is to store fuel before distribution. Oil refineries store lots of chemicals that can cause a wide range of unexpected defects. Some fluids may cause damage that is not clearly understood when in the tank. An RBI inspection company can evaluate the plant and develop strategies to achieve the desired level of reliability.

3. The Horticultural Sector

In recent years, complex machines have been adapted for both large and small-scale farming. An inspection may be critical to ensure compliance with local code and state regulations to enhance safety and boost efficiency.

Plants processing agricultural products may use sophisticated equipment to preserve food. An RBI inspection company can conduct a damage mechanism assessment to determine high risks components. The company may then use NDT inspections to narrow down the areas with the highest risk level.

4. RBI inspection in Nuclear Industry

A nuclear power plant is subject to a wide range of risks during its operation. The manager has to consider factors such as safety, costs, and radiation exposure. An RBI inspection process is crucial in preventing failure that would result in dire consequences.

The plant could face staff shortages due to the complex nature of nuclear facilities. The lack of intellectual resources can raise the risk of failure within the power plant. An RBI company can scrutinize the operation of the plant and the qualifications of the employees in the facility.

RBI Versus Time Based Approaches

Many organizations in the past used Time-Based Inspections that scheduled maintenance based on regular intervals. However, as plants increased their amount of equipment, RBI proved to be more viable. Most machines deteriorate over time, and therefore, it is essential to consider the frequency and impact of use.

An effective RBI process considers several factors that Time-Based approaches overlook. An RBI inspection company can assist the organization with narrowing the scope of its assessments, and it can reduce downtime by optimizing inspections. RBI is essential for modern companies with numerous assets and sophisticated operations to manage. For more information on risk-based inspections, talk to the team at InServe Mechanical Integrity Group today.